Enhancing Asset Inspection with LiDAR-Equipped Quadrone Nivo: Precision and Efficiency

In recent years, asset inspection across various industries—such as energy, infrastructure, and telecommunications—has seen a significant shift toward more efficient and accurate methods. The integration of LiDAR (Light Detection and Ranging) technology with the Quadrone Nivo drone from PT Technogis Indonesia is revolutionizing how inspections are conducted. This combination provides unparalleled precision in capturing high-resolution 3D data of assets, enhancing maintenance workflows, safety, and decision-making.

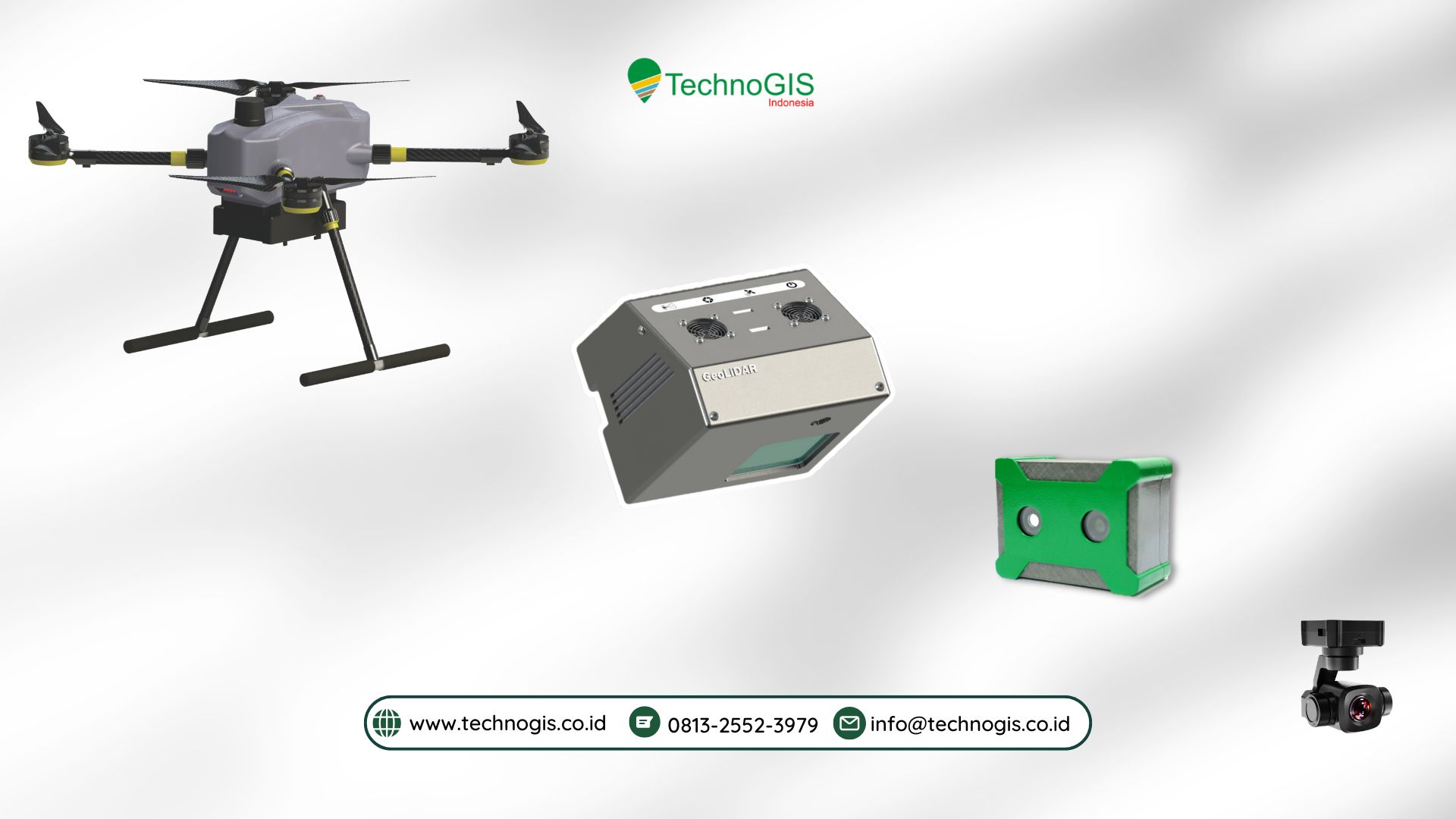

LiDAR-Equipped Quadrone Nivo for Asset Inspection:

The Quadrone Nivo drone, equipped with LiDAR sensors, offers an ideal solution for asset inspection due to its ability to easily navigate complex environments and capture highly accurate spatial data. Unlike traditional methods, which require human intervention and often pose safety risks, the Quadrone Nivo can perform inspections quickly and safely without the need for scaffolding, ladders, or helicopters.

The integration of LiDAR sensors with the Quadrone Nivo allows for the collection of precise measurements of physical structures, capturing detailed information about asset conditions, including cracks, corrosion, and structural deformations. This data is crucial for industries where preventative maintenance is essential, such as in power lines, telecommunications towers, bridges, wind turbines, and oil and gas facilities.

Advantages of LiDAR-equipped Quadrone Nivo in Asset Inspection:

-

High Precision and Detail:

LiDAR systems on the Quadrone Nivo emit laser beams to scan the surface of an asset and record distances based on the time it takes for the laser to return. This process creates detailed 3D models and point clouds that can highlight even the smallest irregularities in an asset, offering highly accurate condition assessments. These 3D models are particularly useful for engineers to inspect the exact shape, size, and structure of assets down to the millimeter level. -

Efficient and Time-Saving:

The Quadrone Nivo equipped with LiDAR can cover large areas in a fraction of the time compared to traditional manual inspections. For instance, inspecting long pipelines, large energy transmission towers, or extensive roof structures is significantly faster with the Quadrone Nivo. This leads to cost savings and ensures that assets are regularly monitored without long downtimes. -

Improved Safety:

In hazardous environments such as tall structures, remote installations, or areas with difficult terrain, drones like the Quadrone Nivo provide a safer alternative to human workers. They can access hard-to-reach places without the need for scaffolding, ropes, or ladders, thereby reducing the risk of accidents and injuries. This safety aspect is especially critical in industries like energy, where high-voltage equipment and challenging weather conditions can pose additional threats to human inspectors. -

Real-Time Data Processing:

The integration of real-time data processing with the Quadrone Nivo allows operators to quickly identify issues as soon as data is collected. This can be particularly important for mission-critical assets, where fast responses are required to avoid downtime or prevent more severe damage. With advanced software, this data is transformed into actionable insights almost instantly, enabling companies to make decisions and deploy maintenance crews faster. -

Remote and Difficult-to-Access Locations:

One of the primary benefits of using the Quadrone Nivo for asset inspection is its ability to reach remote or difficult-to-access locations, such as offshore oil rigs, high-voltage powerlines, or remote pipeline sections. LiDAR technology combined with the Quadrone Nivo‘s mobility ensures that inspectors can obtain accurate readings and 3D models of assets, even in the most challenging environments.

The fusion of LiDAR technology with the Quadrone Nivo has revolutionized the field of asset inspection. By providing accurate, real-time, and comprehensive data, these drones help industries conduct inspections faster, more safely, and with greater precision. As technology advances, the use of drones in asset inspection will only continue to grow, enabling companies to reduce operational costs, improve safety, and make more informed maintenance decisions.

Leave a Reply

Want to join the discussion?Feel free to contribute!